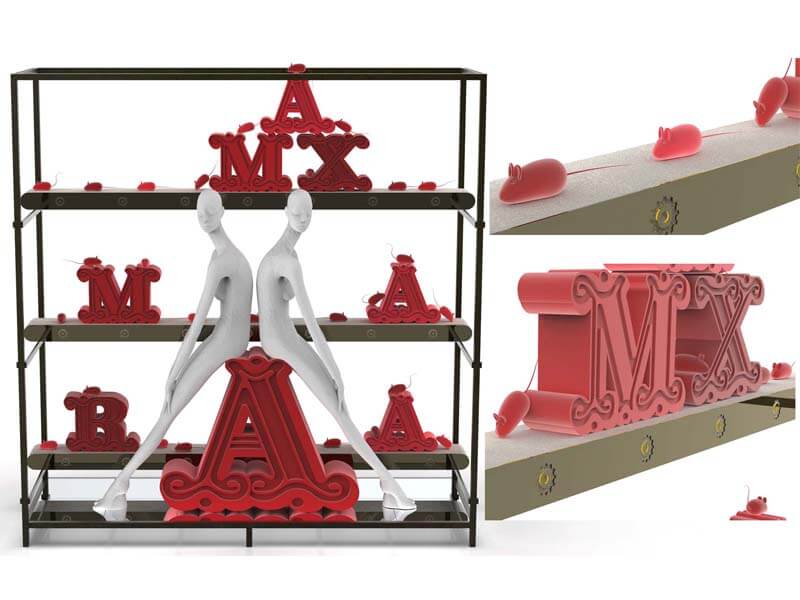

Introduction of Nano-spraying from DM Window Display

As a window display manufacturer, DM Window Display provides display props with integrated materials and processes, like painting, engraving, polishing and electroplating, etc. But for the electroplating, there are many different types of it. It includes heat electroplating, Nano-spraying, and PVD (Physical Vapor Deposition) etc,. Now we’d like to talk about something about Nano-spraying.

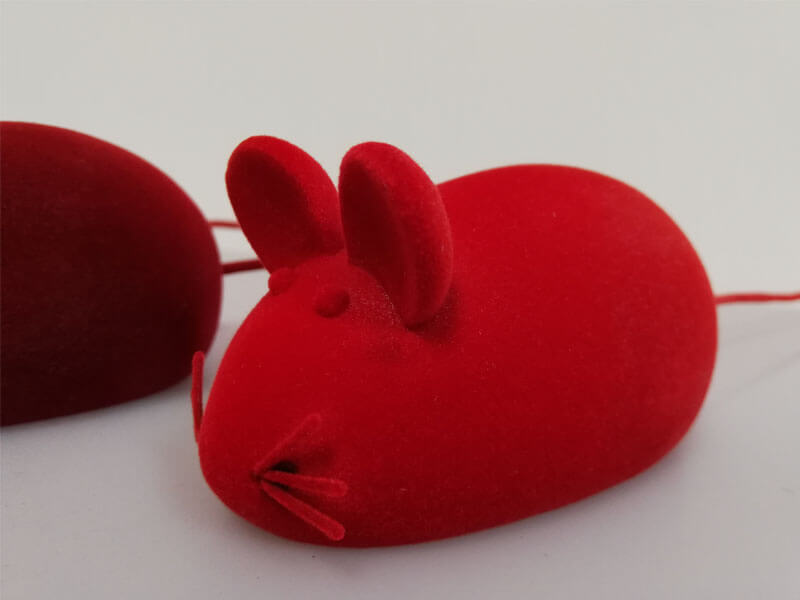

Nano-spraying is the world’s most advanced high-tech spraying technology. It always adopts special equipment and advanced materials, and then chemically make the surface of the object to be coated with various specular highlights such as gold, silver, chrome and various colors ( like red, yellow, purple, green and blue) by direct spraying.

The products sprayed by Nano-spraying have the advantages of excellent adhesion, impact resistance, corrosion resistance, weather resistance, abrasion resistance and scratch resistance, and are with good anti-rust properties. They are generally used by large automobile manufacturers in domestic and abroad market. Such technology is used for surface treatment of precision products for large electrical appliance and car manufacturers, as well as surface decoration and protection for other industries. The process is simple, environmental and versatile, and it is a really high-tech surface treatment technology.

But actually Nano-spraying is a process in which a silver mirror reaction uses a spray gun to spray a silver ammonia solution onto the surface of an item. All the sprayed out finishes are silver, and then the surface protection solvent is added with appropriate color to form different various colors.

But Nano-spraying has some certain limitations, and it would be best to be used in some fine finishing and avoid to spray the items with high-pressure friction.

Nano-spraying is also belong to electroless plating. Then what’s the advantages and features of the Nano mirror surface.

- Environmental protection–no heavy metal and no three wastes.

- Low investment and low cost

- Operational safety – no damage to the sprayer during operation.

- Suitable for automated production – automated production line according to customer needs.

- Diversified colors – golden yellow, brass, antique golden, gunmetal, red, yellow, purple, green, blue, etc.

- Recycling–sprayed plastic products can be crushed after being discarded, and then recycled and reused.

- Wide range of applications – substrates of various materials can be sprayed, regardless of volume area.

- It can be used for inter cross color spray–can be used for the color decoration of the partial spray, and also the pattern of different colors and effects on one product.

Email:liona.dm@displayformore.com

Email:liona.dm@displayformore.com  Tel: +86 13400652499

Skip to content

Tel: +86 13400652499

Skip to content

Leave A Comment