2019 Coach Christmas Shop Window Display from DM

As known, Coach, a renowned affordable luxury brand’s shop window displays are fabulous and gorgeous all the time, and even highly praised as benchmark in window display industry. The stories that the windows tell are always full of creativity and novelty, which would slow those folks down and even stop them in their tracks. So do the Coach’s Christmas window display of 2019

Fortunately, DM Window Display was really excited to be previledged as the Christmas tree supplier to join the 2019 Christmas window bespoke for Coach. Without all doubt, it would be a big and much-anticipated worldwide visual project, do please expectation!

Grand project always begins early.

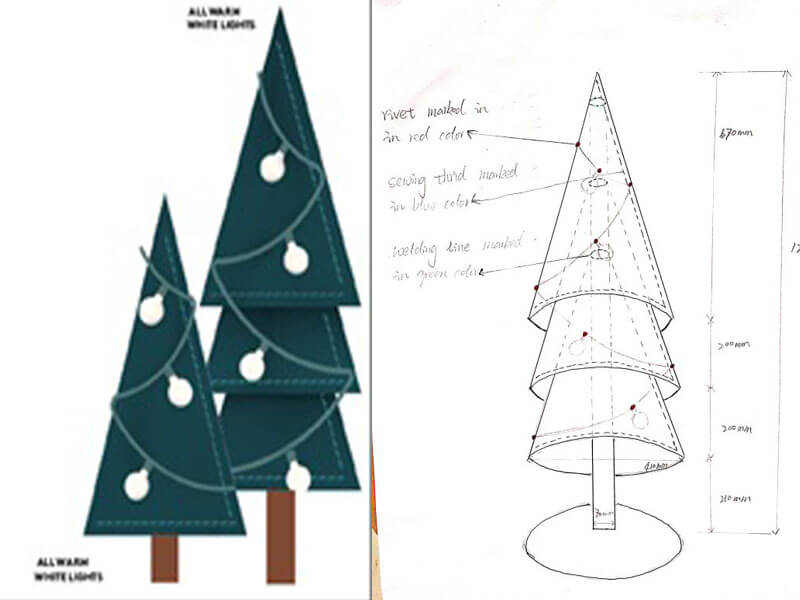

Since April of 2019, we got the initial simple 2D draft of Christmas trees. There are four types of tree: window large tree, window small tree, instore large tree and instore small tree.

The right one is the requested simple 3D design sketch.

Armed with a mood board and an open mind, as well as in line with Coach’s initial idea of appearance and quality, we suggest the material and production process as below:

- Handmade metal tree-shaped cone and trunk;

- Weld the trunk to every layer for fixation;

- Stitching 2 1cm distance-to-edge strings for decoration line on PVC leather, and then glue the leather on the metal tree-shaped main body;

- Drilling small holes on the surface for hanging light bulbs;

- MDF material base, and screwed to the trunk for standing on floor.

First prototype production.

After getting approval of first round quotation, we started first round prototype production. Firstly, metallic PVC leather is stitched to be a cone shape and wrapped over the metal tree.

Then we drilled holes for hanging lighting bulbs. The trees really looked amazing with various colors bulb lights on, presenting so stereoscopic and creative Christmas trees.

We couldn’t wait to send them to client for their review, and as was expected, they were quite satisfied with the trees and spoke highly of our structure design and finishes.

But first prototype would never be the final design, and we all knew that designers always had more acute and creative design vision, so they upgrade the drawing for the second prototype.

Second prototype production

To be honest, We were really amazing and exciting when got the second drawing from Coach, as the color assortment was much more high-end and looked gorgeous. For instance, they changed the color of tree from metallic dark green leather to solid bright green with pearl white snow cap on the top. And the pearl white snow cap cover the green tree just like real snow naturally falling on the tree, which help create more Christmas atmosphere.

Following clients’ intention clearly, we suggested making the snow cap with acrylic material bending the shape with 200℃degree in oven. And then painted the acrylic cap to be high glossy pearl white with car paintings, then fixed it on the tree structure by special super glue.

Here are the second samples.

Fortunately, after Coach reviewing the second sample, the good quality and upgrade tree structure were exactly what they want, and they finally approved that DM Window Display to bes their final Christmas tree supplier — Then we started the journey to join in 2019 Coach’s Holiday window bespoke big party, suppling Christmas trees all over the world for Coach’s Window.

Mass Production

Finally, we got confirmed order at the beginning of July then started to prepare materials for production at once.

Before mass production, we firstly worked out a production schedule which indicated the ready time for every materials, like

Tree structure ready date: July 13th

PVC leather stitch ready date: July 15th

Acrylic cap ready date:18th

Tree Assemble and package date: July 24th

First delivery: End of July

After preparation time confirmaed, then we began:

All metal tree structure cone shaped with tree trunk painted in glossy color.

Four types of tree cones: small one layer, small three layers, large one layer and large three layers.

Color customized PVC leather. Cutting the leather to be cone shaped and stitching for metal tree-shaped body wrapping.

Wrapping the tree cone outside with exclusive leather by special glue and accurately calculating & controlling the decorative line to be 1cm distance to the edge, making sure the decoration line being straight and neat.

Additionally, gluing a 5cm width leather strip inside of the metal tree, so that the galvanized metal structure is invisible even on the high shelf display.

Engraving acrylic sheet to be flat fan shape, ovening the plate with 200℃degree temperature, and then bending it with metal mold as cone shape to suit the Christmas tree shape.

In order to make sure every snow cap glued on the tree was the orientation, we made a simple wave-shaped acrylic mold to fix the right position, and then attached it to the metal surface with exclusive mighty glue.

Besides, considering the limited height of shelf display for in-store small tree, We figured out a height-control box, measuring the height for every tree before package to make sure the tree could be displayed on the shelf without any problems.

Bearing Coach’s design in mind that there would hang different colors of light bulbs on the tree, we need to drill holes for lights hanging. But there are so many thousands of trees, how to make every holes of different trees in the same place in a relative short time?

We came up many ideas and tried may times, finally: making a paperboard as a standard mold, then drilling holes on the paper mold so as to make sure every hole on the tree is in right position.

Every time we make out production sample, we would put it on our MOCK Window to show to check the final display effect.

QC Inspect DM Factory on site

Inside package, as the acrylic snow cap is fragile, we use seven layer cardboard carton with honeycomb cardboard to protect the snow cap to make sure its safety when delivered.

External packing:

And for in-store small tree, we put every 16 cartons to a outer wood crate, and 8 cartons to a wood crate for in-store large tree, all in-store trees were packed by country allocation as per Coach’s request.

For Window Tree, all trees were packed as per store allocation and SKU allocation and label clearly attach on outside to show the country name, store name and SKU number.

Delivery: The production lead time for the whole project lasts about 50 days which from middle of July and early of September. Partial shipment started from July 30th and middle of September.

As a VM supplier, all the members of DM team are so proud to complete the entire process from just a simple 2D draft to design, two rounds of prototype, mass production and delivery to clients’ store . And we’re also delighted to have yet another prestigious international Luxury brand working with DM Window Display, recognizing our turn-key production capacity and facilities as an ideal and partner for their stores throughout the world.

Thanks for the trust and cooperation, and we do believe that the Christmas tree would make a real statement in Coach’s Christmas shop windows with a positive impact on sales.

So let’s just enjoy the fabulous Christmas window display of Coach 2019!

Email:liona.dm@displayformore.com

Email:liona.dm@displayformore.com  Tel: +86 13400652499

Skip to content

Tel: +86 13400652499

Skip to content

Leave A Comment