Project Description

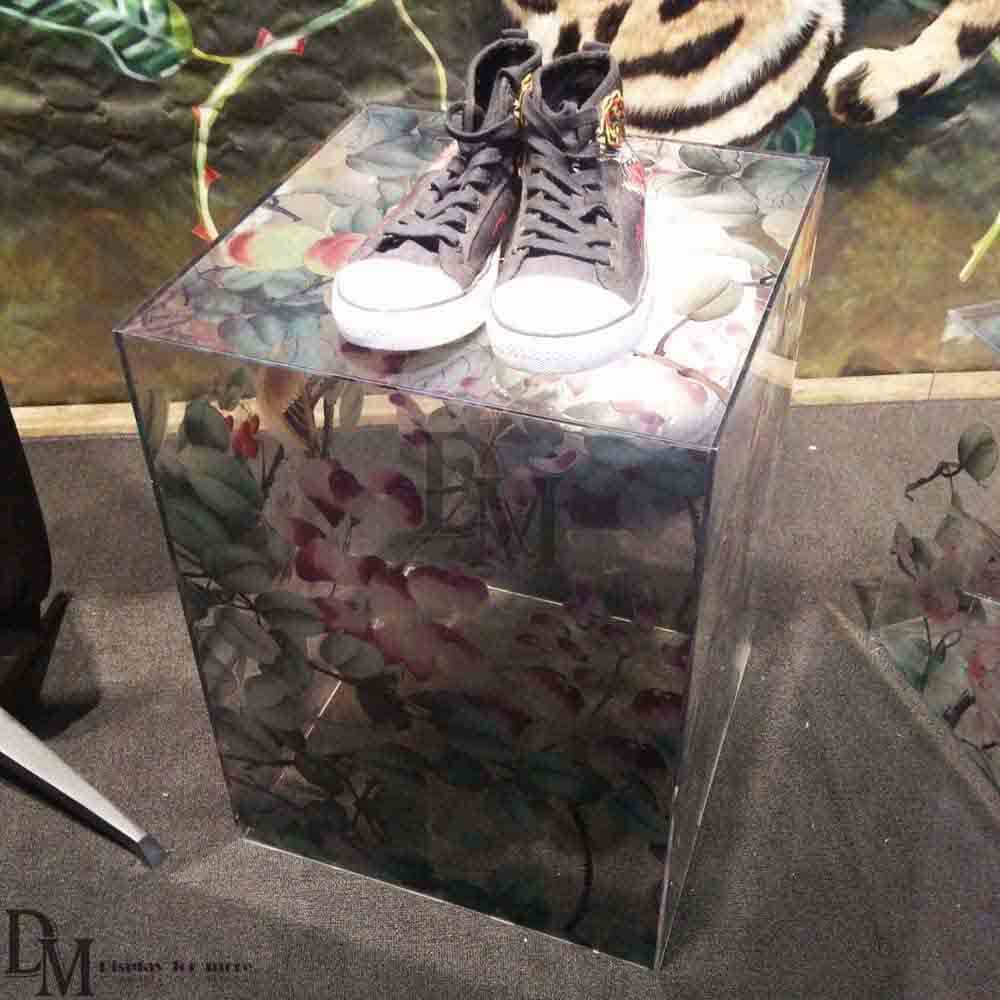

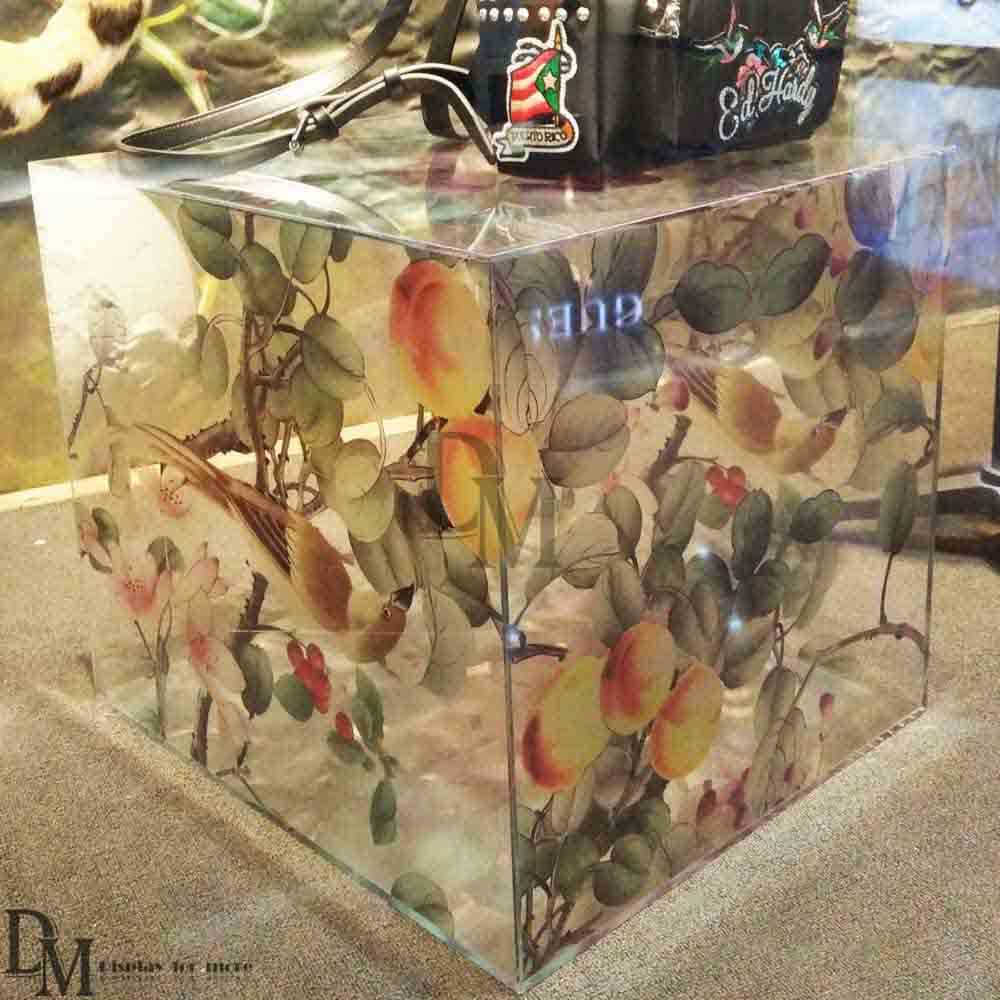

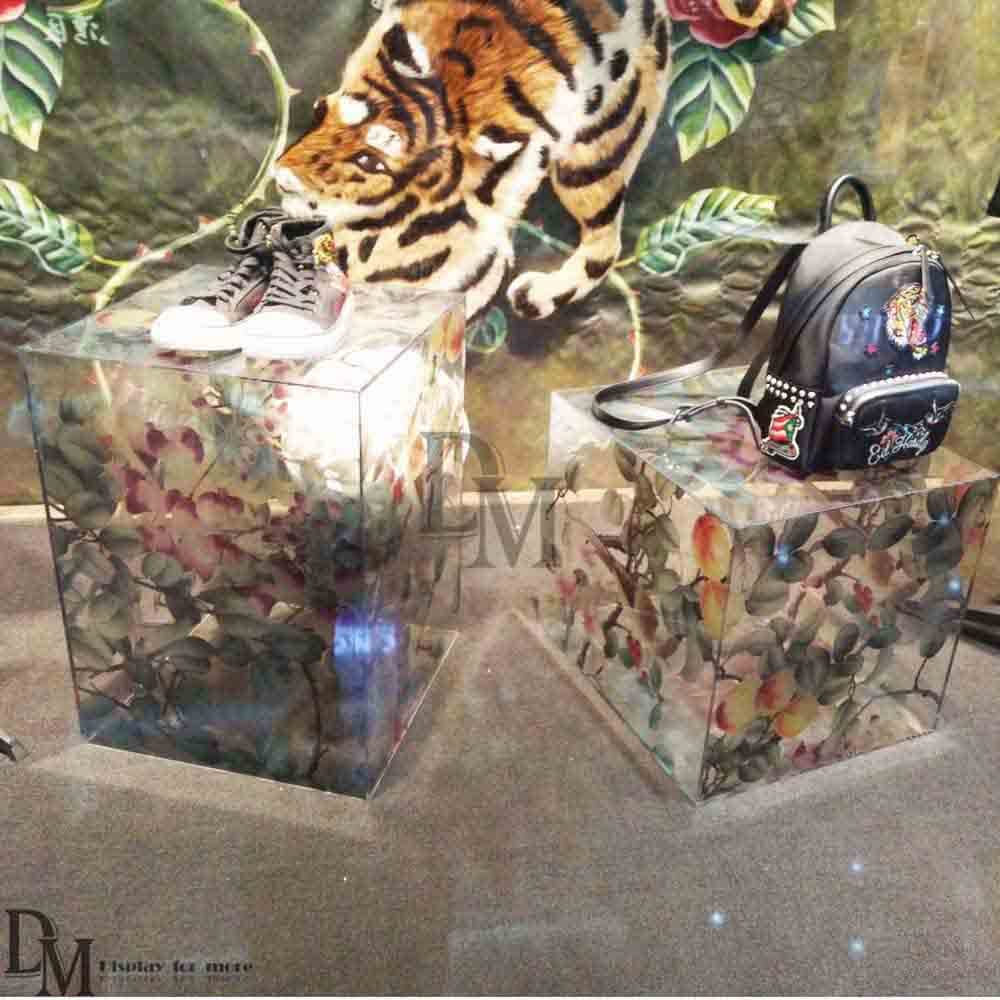

Acrylic Window Display Stand for Clothes and Accessories Showing

Item No.: DMAC17111404

Brand Name: DM Display

Materials: 100% Acrylic

Size: 40x40x40cm and 40x40x55cm or customized sizes depend on you

Color finish: Transparent with silk printing flowers.

Weight: Around 2-5 kg

Cetification: SGS, ROHS

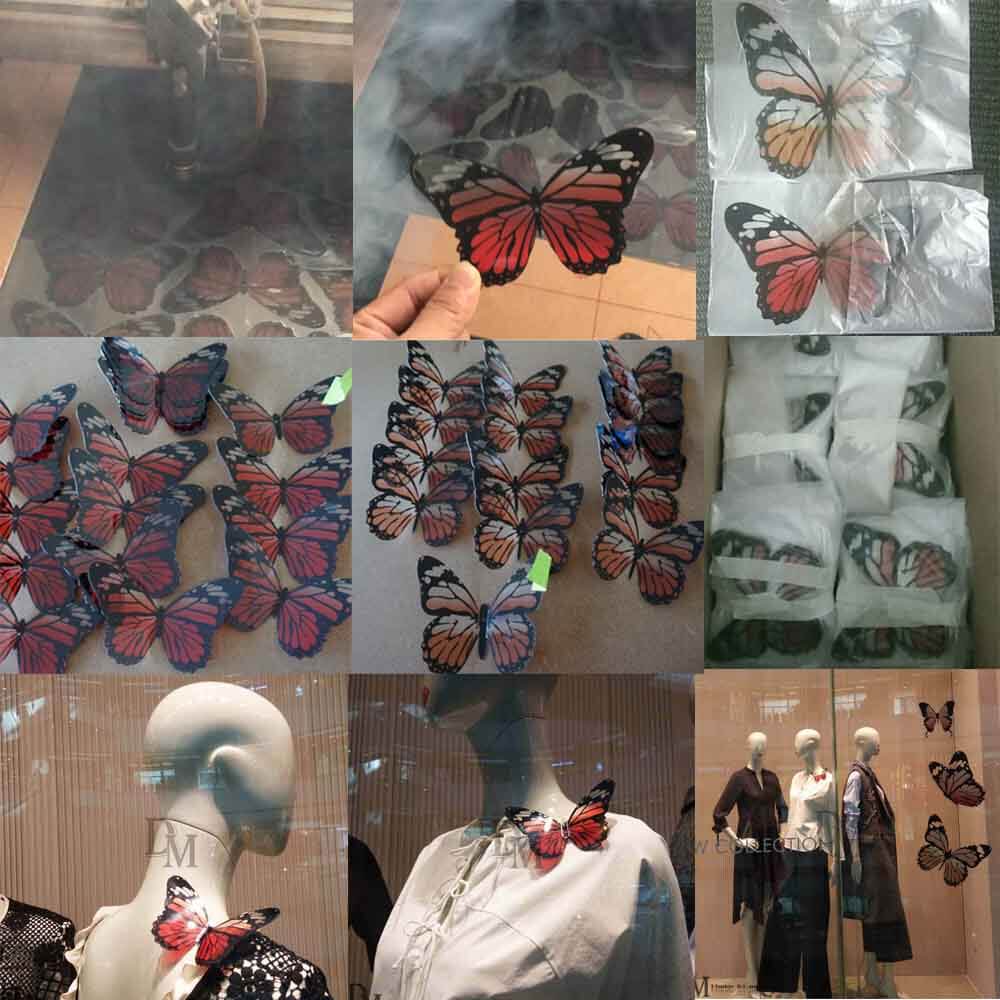

The Spring window display shows out various flowers blooming. It is simple square acrylic window standers with printing flowers as bag and shoes displayers. Welcome to visit DM factory and your own projects for your store window decoration.

- Good silk printing flowers on each side of acrylic stander, square, round shapes for choosing.

- The special bevel bonding to fix total five sides for a square stander. It is complicate tech for bonding.

| Package | sealed bag wrapped with Pearl cotton into carton |

| ent term | 30% T/T deposit, 70% balance before delivery;

100% L/C at sight; Western Union; Paypal |

| FOB/FCR port | Xiamen / Fuzhou / Quanzhou |

| MOQ | 200 pcs per design |

| Delivery time | Around 30 days |

| Sample time | Around 10-12 days |

| Shipping way | By sea / air / express / door to door service |

| Application | Fashion store/shop window display; Store promotion gifts; ornaments for events supplies etc. |

Hardness is one of the indicators to judge the quality of acrylic plate, the average Duroc hardness of about 8 or 9 degrees. There are many different levels of acrylic material in market, so please make decision after checking the finish item.

The bonding is a very crucial process in the processing of acrylic products, how to show the clear and transparent plexiglass characteristics, reflect he value of acrylic crafts and maximize the grade of acrylic crafts? The bonding technology has played a decisive role.

Plexiglass plate bonding mainly affected by two aspects, one is the applicability of the adhesive itself; the second is the bonding skills. There are mainly two types of adhesives on the market, one is two-component, such as all-purpose adhesive, epoxy; the other is one-component. In general, a two-component adhesive is cured by a curing reaction, and a one-component adhesive is a solvent that eventually evaporates to bond.

Two-component adhesive is characterized by good bonding effect and no bubbles after bonding, not white after long time and high strength. The disadvantage is that the operation is complicated and difficult, curing for a long time and slow, also it is difficult to adapt to the requirements of mass production.

One-component adhesive is characterized by high speed and meet the batch production process requirements. The disadvantage is easy to produce adhesive bubbles, white and poor weather resistance, which has a direct impact on the aesthetic appearance of plexiglass products quality.

Below we have several common bonding process:

- Butt to butt bonding

- Facade bonding

- Bevel bonding

- Surface bonding

It commonly uses the acrylic laser cutting machine to make out different shapes of acrylic items, it widely used in advertising industry, like advertising logo words or drafts, acrylic items for store window display.

Below is Industry applications of laser cutting machine:

1. Slim light box cutting 3mm-8mm generally 60W cutting can be. But 80w speed is relatively faster, the time used is also lasting, recommended 80w

2. Acrylic decoration strong 3mm acrylic recommended 80W. Cutting effect is good, fast.

3. Acrylic 10mm-15mm Recommended 100W, three-phase high with acrylic cutting machine.

4. Acrylic 15mm-25mm Recommended 150w, three-phase high with acrylic cutting machine.

5. Acrylic 20mm-30mm Recommended 180w, three-phase high with acrylic cutting machine.

Fast reaction to any customers’ complaint. Replay within 12 hours as usual.

Guide customers how to install with picture process or videos.

Replace new ones if something wrong with goods after checking of QC.

Price term: FOB /CFR from Xiamen Port or Fuzhou Port

Payment term : 30% TT as deposit, 70% balance before shipment

L/C at sight

Western Union

Paypal

Sample lead time: 6-8 days (our current design) ,7-15 days (customers design).

Production time:35-45 days (up to your QTY) upon receiving the deposit.

Inner packing: PP bag or Bubble wrap over each product, styrofoam around item.

Outer packing: Heavy cardboard carton, or wooden box.

Yes. It is our advantage to make customized projects, from your pictures or detail design drafts, first make out sample for your confirmation, then start production. If you would like to know more information, you can check our detail Services

10-50pcs according to different projects. Warm welcomen sample order (1-10pcs) , test order (10-50pcs) , mix order (differnt kinds of product)and big order (5000+).

Monthly capacity: Around 500-1000pcs per month.

A, Customer provide original sample —- We make mass production base on original sample. Sample lead time: Around 10-15 days

B, Customer provide draft picture or photo —- We make clay sculpture —- to make mould —- to make mass producton. Sample lead time: 15-20 days.

One-step service of complete solution for display project

Integrated supplies various materials for window display props

Customized as per client’s request

If you would like to know more, pls check our other page About DM

Our company provides different materials of props for window display, commercial mall display, plaza display and home décor. So we could offer different items for a whole complete display projects, but our main advantage items are Fiberglass statue (Animal statue, cartoon statue, fake food statue, and other customized shape statues), wooden craft decoration (like photo frame, tray, box, clock, cabinet, furniture, etc.) metal/iron display (Industrial furniture, metal display etc.)

Not yet. But we would like to find a good agency to achieve a win-win situation. Our advantage is customized fiberglass / resin statue, wooden home deocoration ( Antique, shabby chic, rustic styles), Industrial display / furniture, FRP furniture.

If you are interested in this product, please send us without any hesitate!

Email:liona.dm@displayformore.com

Email:liona.dm@displayformore.com  Tel: +86 13400652499

Skip to content

Tel: +86 13400652499

Skip to content